High Precision with Wire EDM

Wire EDM (Electrical Discharge Machining) is a machining technique that uses a thin metal wire to cut through materials with extreme precision. This technique is ideal for creating complex and detailed geometries in hard-to-machine materials. Wire EDM is one of the most efficient methods for making accurate cuts in metal, plastic, and ceramics, and is used in everything from tool manufacturing to advanced technology.

What Is Wire EDM?

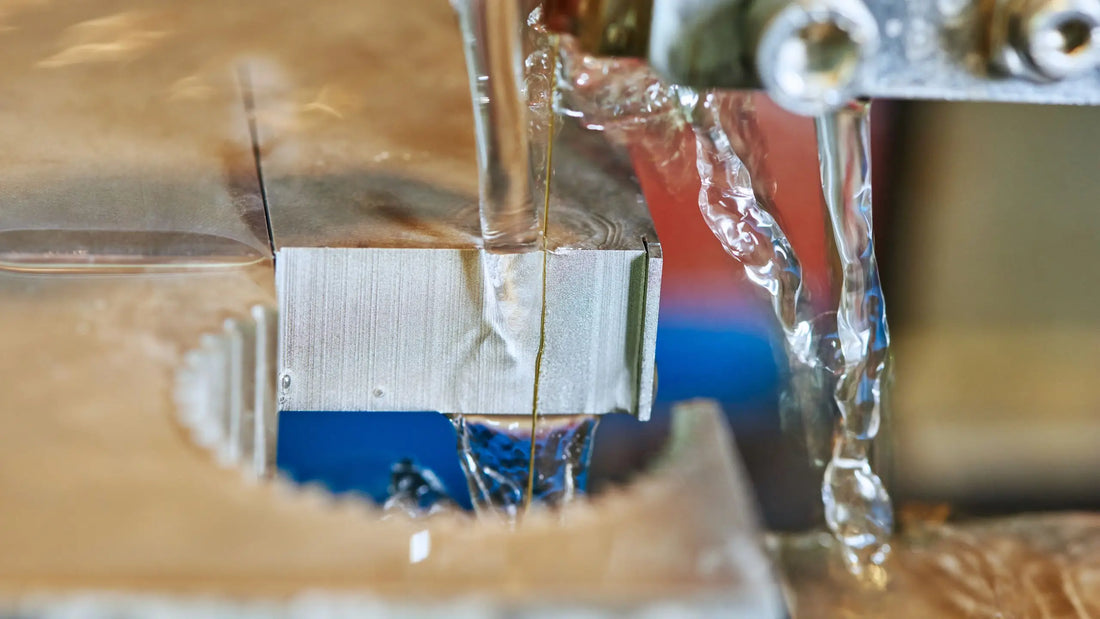

Wire EDM involves a thin, electrically charged wire moving through the material, creating small electrical discharges that melt away the material in exactly the patterns and cuts required. Here’s an overview of how the process works:

Step-by-Step Process for Wire EDM:

- Prepare the Workpiece: The workpiece is placed in a dielectric fluid, which acts as both an insulator and coolant.

- Guide the Wire: A thin wire made of copper or brass moves through the workpiece according to the desired pattern design.

- Electrical Discharge: When the wire comes into contact with the workpiece, small sparks are generated, melting and removing the material.

- Fine Tuning and Post-Processing: The electrical discharge is repeated to create the exact cuts and details, and polishing may be done to enhance the finish.

Advantages of Wire EDM

Wire EDM offers several advantages that make it an unbeatable technique for creating complex and precise components:

- High Precision and Accuracy: Create extremely detailed cuts and patterns with minimal tolerance.

- No Mechanical Stress: Since the wire doesn’t touch the material directly, the risk of deformation is avoided.

- Cuts Through Hard Materials: Process even hard-to-machine materials such as hard metals, steel, and ceramics.

- Design Flexibility: Create highly complex and intricate shapes that would otherwise be difficult to achieve.

Applications of Wire EDM – When Precision Is Critical

Wire EDM is used across various industries where precision and complexity are essential. Here are some of the most common applications:

- Tool and Mold Manufacturing: Wire EDM is used to create detailed tools and dies (molds) for stamping, pressing, and shaping.

- Automotive Industry: Manufacture complex components for engines, gearboxes, and other high-precision parts.

- Medical Technology: Create small, precise components for medical devices, such as implants or surgical instruments.

- Aerospace: Process components for aircraft engines and other critical parts where high precision is crucial.

Limitations of Wire EDM

Despite its many advantages, there are some considerations to keep in mind when it comes to Wire EDM:

- Time-Consuming: The process can be slow, especially for large or highly detailed components.

- Limited Material Thickness: Wire EDM is best suited for cutting through thinner materials, which can be a limitation when processing thicker workpieces.

- Cost: The equipment and process can be expensive, making it essential to carefully evaluate its use for each specific project.

Wire EDM – The Ultimate Solution for High Precision

Wire EDM is an unparalleled technique for creating detailed and complex cuts in a wide range of materials. With its ability to process hard-to-machine materials and create precise shapes, it is an indispensable method for industries where precision is critical. By understanding both the advantages and limitations of Wire EDM, you can use the technique to its fullest potential to create top-quality components.

Need Help with Wire EDM?

Mora Tool offers expert knowledge and advanced equipment for Wire EDM, enabling us to deliver high-precision and complex details tailored to your specific needs. Whether you’re in tool manufacturing, the automotive industry, or medical technology, we can help you develop the perfect components for your production. Learn more about our Wire EDM services below.